Using Human Factors to Unlock Your Product's Potential

by Teresita Pileggi

As mentioned in my previous blog post, "Recap of the 2025 Combination Products Summit" my colleague, Sara Waxberg McNew, and I had the pleasure of presenting a spotlight on Human Factors Engineering (HFE) at the summit. Below I will dive deeper into our presentation, "Beyond Validation: Unlocking the Full Potential of Human Factors Engineering" to elaborate on one of the specific case studies we presented that highlights a real-world example of applying HFE throughout the product development process. Then, I will provide a high-level overview of various additional HF activities available for manufacturers to strengthen their overall submissions.

Taking Human Factors Above and Beyond Validation Studies

When most people think of HFE, they think of validation activities, as validation studies (also known as summative studies) are frequently required for medical device and combination product regulatory submissions. However, HFE can and should be utilized for additional assessments throughout the product development process prior to validation studies. Incorporating HFE activities throughout the product development lifecycle provides assurance that medical products have been designed for the correct intended use(s) and that they meet their design input requirements. As outlined in AAMI TIR59:2017 Integrating human factors into design controls, HFE is most impactful if incorporated iteratively throughout the entirety of the product development lifecycle and not viewed as a “checkbox activity” at the end of validation to be able to submit to regulatory bodies. Our presentation at the summit highlighted some overlooked areas of opportunity to integrate HFE assessments and techniques to not only design safe and effective products, but to maximize user satisfaction and reduce development costs as well.

Case Study

I want to highlight one of our case studies presented to give a more tangible example. Imagine that a manufacturer has developed a new medication to treat Rheumatoid Arthritis (RA) that they would like to market as a combination product using a prefilled syringe. As such, they will need to create instructions for use (IFU) and secondary outer packaging for this new syringe, as well as confirm that their intended user population is able to use the product to deliver a dose successfully.

There are a few concerns and considerations the manufacturer must keep in mind for this particular new product:

RA patients may have warmth and swelling of joints, stiffness episodes lasting 1+ hours, constant or recurring pain in the joint, and/or difficulty using or moving joints, making it difficult to complete some tasks.

The outer packaging of the syringe needs to be easy enough to be opened by RA patients who may be experiencing a flare episode, but still rigorous enough to pass child resistance requirements.

RA patients may also experience negative transfer when using a new product since many have used other RA injectable devices in the history of their diagnosis. Negative transfer occurs when the lessons learned using one device do not apply to another one, leading to potential use problems induced by incompatible designs or functions.

Here are a few HFE strategies this manufacturer could employ:

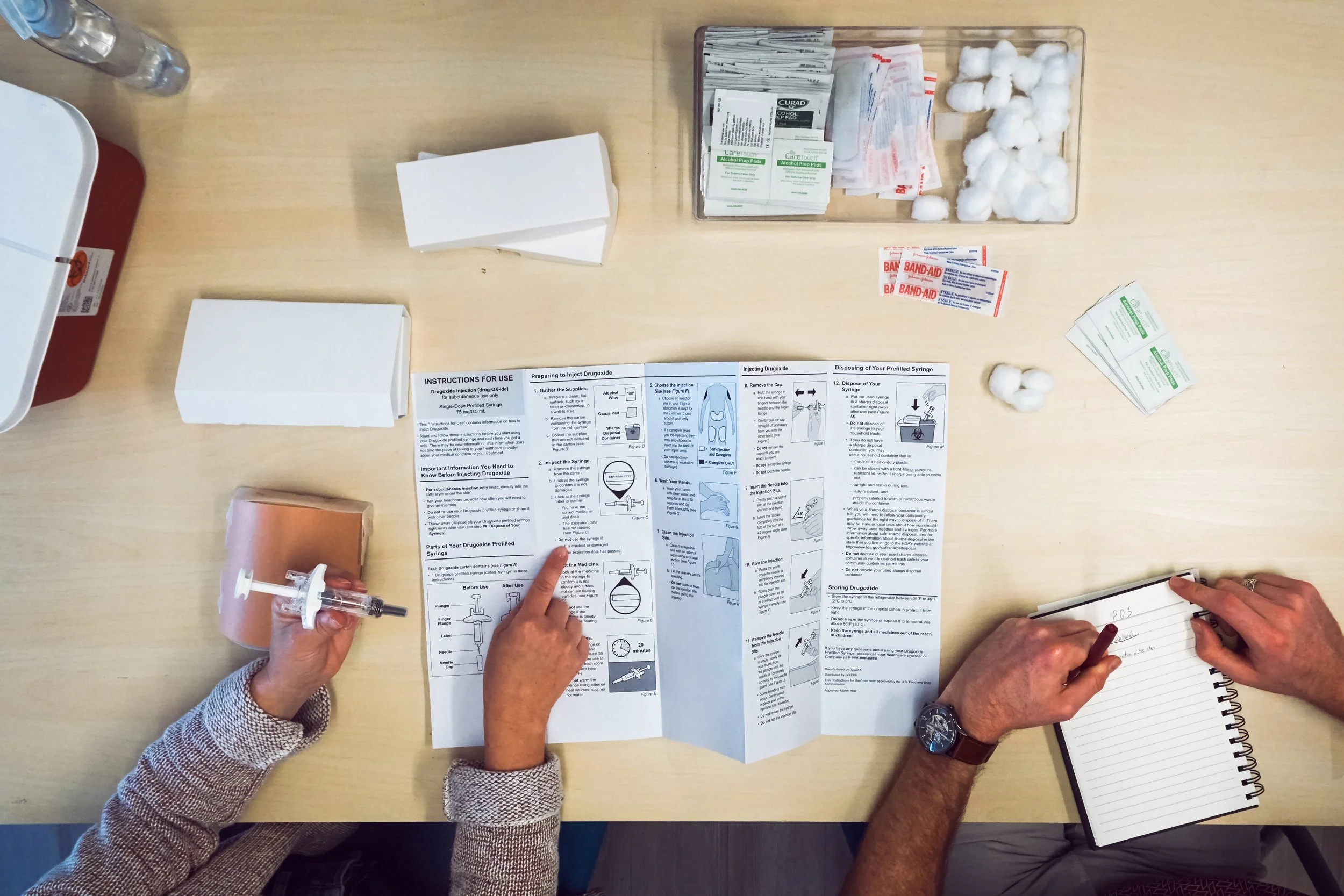

Force Injection Study: Execute a formative usability study with representative RA patients to measure injection time, required force to inject, and collect force acceptability assessments. This injection data can help identify the maximum force that the RA patients are able to inject with the syringe. This study would also give the patients the ability to assess other critical tasks associated with the syringe.

Iterative IFU Testing: Review IFU drafts with small batches of representative users to gather feedback, align and implement changes, and then retest with additional users for 2-3 iterations to fine-tune the IFU and home in on the instructional language.

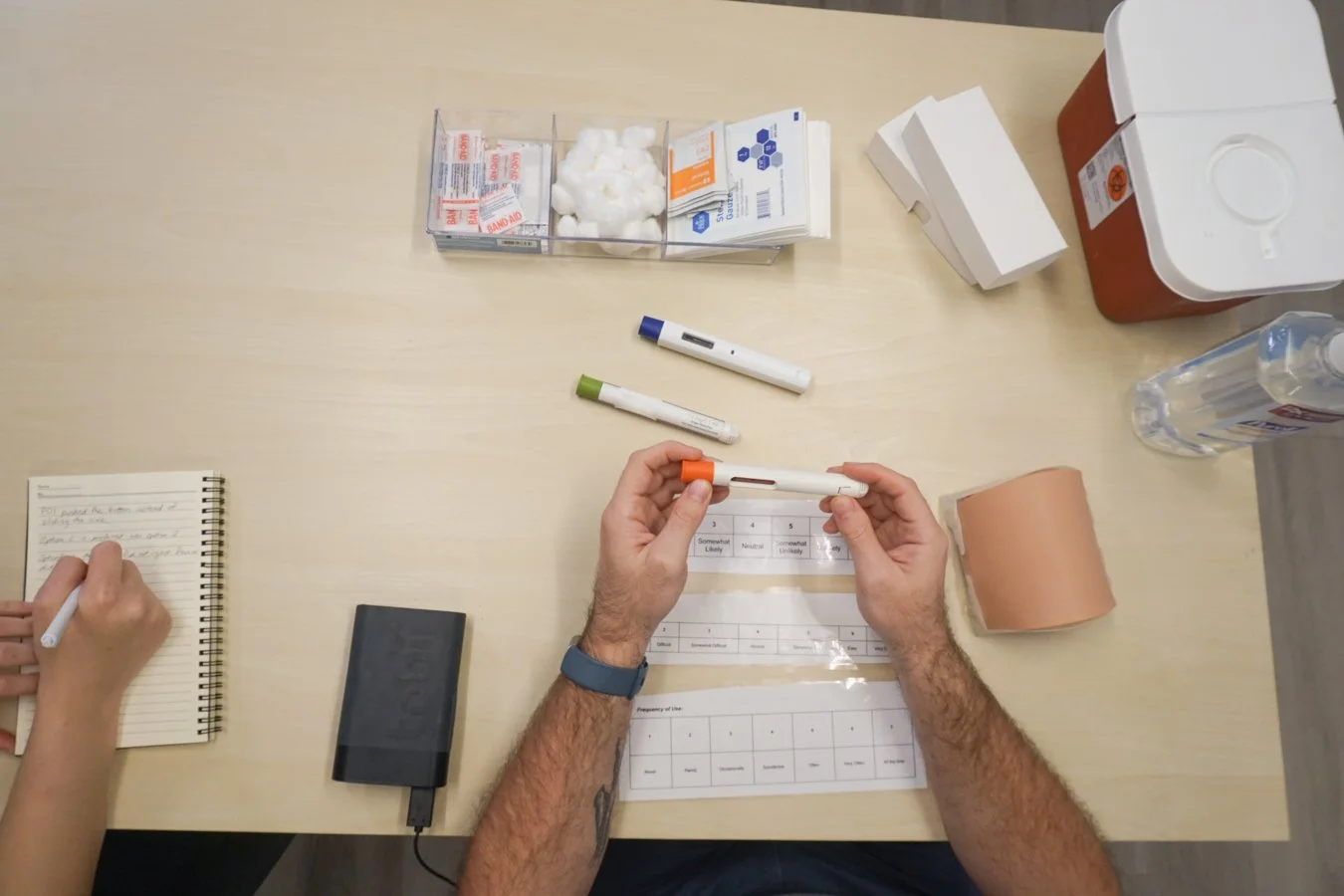

Packaging Rankings & Ratings: Present representative users with multiple packaging or labeling options, sometimes with the ability to workshop live, for users to provide overall ranking of preferred options, or ratings of various features or components to highlight the ‘best’ versions for manufacturers to proceed with developing.

These activities could be completed together, or in separate smaller instances depending on the speed at which certain elements of the product's development are ready for review. For example, the syringe acceptability would likely occur before spending time and money to design the IFU and outer packaging.

Additional HF Activities

Throughout our presentation at the summit, we walked through a handful of case studies similar to the one above to highlight some of these earlier HFE activities and how they could be applied throughout various product development phases for different combination products such as prefilled syringes, autoinjectors, and oral medications. A sample of the HFE activities that can be utilized are included below for reference:

Injection Force Studies

Human Capability Requirements

Field Research & Contextual Inquiry

Comparative Evaluation

Heuristic Analysis

Expert Review

Early & Later Stage Formative Studies

Iterative IFU Testing

Rankings & Ratings

User Feedback During Clinical Trials

Integrating HFE methodologies through the product development cycle guarantees that the voice of the user is heard throughout the process and helps to ensure that there are minimal surprises by the time validation testing comes around. Additionally, demonstrating that HFE activities were leveraged in multiple instances during development makes a stronger case for the overall product’s safe and effective use.

If you're interested in any of the opportunities I have highlighted to bring HFE into your product development process sooner rather than later, take a look at Design Science's offerings and reach out to connect with us. We are happy to support your team's human factors activities in whatever phase of product development you are at!